An automatic filter press is a highly efficient machine that streamlines filtration processes in various industries. It operates using a series of plates and filter cloths to separate solids from liquids, resulting in optimal filtration outcomes. By automating the process, the filter press reduces labor costs and minimizes operator error. Its applications are diverse, from wastewater treatment to food processing. This article will explore the working principle of an automatic filter press, its advantages, and its various applications.

Introduction

An automatic filter press is a powerful machine that has revolutionized filtration processes in many industries. It is a highly efficient and cost-effective tool that uses a combination of mechanical and chemical processes to separate solids from liquids. By automating the process, it reduces labor costs and minimizes operator error. This article will delve into the working principle of an automatic filter press, its advantages, and its various applications.

Working Principle of Automatic Filter Press

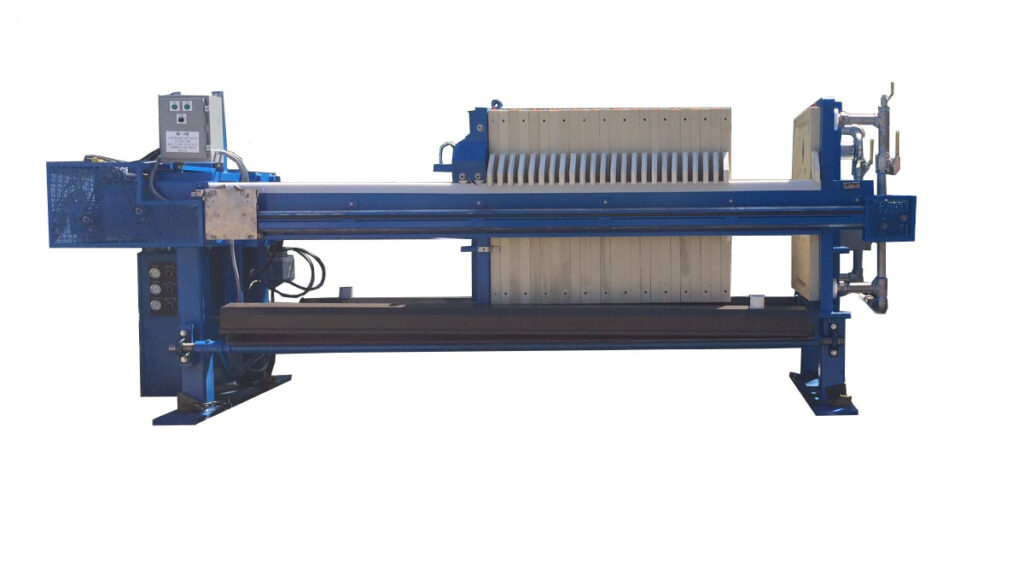

The automatic filter press operates using a series of plates and filter cloths. The plates are arranged in a stack and are connected through a hydraulic cylinder. The filter cloths are placed between the plates, and the hydraulic cylinder applies pressure to the plates, compressing the filter cloths. The pressure forces the liquid through the filter cloths, leaving the solid particles trapped inside. The filtered liquid is collected in a separate container, ready for use.

Advantages of Automatic Filter Press

The automatic filter press offers several advantages over traditional filtration methods. Firstly, it is highly efficient and produces optimal filtration outcomes. Secondly, it is cost-effective and reduces labor costs. Thirdly, it minimizes operator error, ensuring consistent filtration results. Finally, it is environmentally friendly, as it minimizes waste and reduces the need for harmful chemicals.

Applications of Automatic Filter Press

The automatic filter press has a wide range of applications across various industries. It is commonly used in wastewater treatment, where it efficiently separates solids from liquids, producing clean water that can be safely discharged back into the environment. It is also used in the food processing industry, where it separates solids from liquids, producing high-quality food products. Additionally, it is used in the mining industry, where it separates valuable minerals from waste materials, reducing environmental impact.

Example of Automatic Filter Press in Action

An example of the automatic filter press in action is in the production of olive oil. Olive oil production involves separating the oil from the pulp and seeds of the olives. Traditionally, this was done using a manual press, which was labor-intensive and produced inconsistent results. With the introduction of the automatic filter press, the process has been streamlined, producing high-quality olive oil with minimal labor costs.

Conclusion

The automatic filter press is a highly efficient and cost-effective machine that has revolutionized filtration processes in various industries. Its working principle is simple, yet effective, using a combination of mechanical and chemical processes to separate solids from liquids. Its advantages include optimal filtration outcomes, cost-effectiveness, and environmental friendliness. Its applications are diverse, from wastewater treatment to food processing. The automatic filter press is a valuable asset for any industry looking to streamline its filtration processes and produce optimal results.