The wheel is weighted so its energy will keep up with the movement of the shaft.

A fly press which is worked by hand is the just of all presses, it comprises of mass, manage, body, arm, screw, slam, stop collar, tracks, and guides. A screw press is a kind of machine press in which the slam is moved all over by a screw. It works by utilizing an unpleasant screw to change the pivot of the arrangement with or drive-wheel into a little descending movement of higher tension.

We expected to give them a stage that would give them all that they had to be aware concerning the drug store area. And all the substance material on this Pharmacy Scope site is presented with sincere intentions and exclusively to give normal data. In the event that utilized as a punch, the actual device comprises of a punch and a matching pass on, into which it eagerly suits. The material is presented between the punch and kick the bucket, and the machine worked. The punch will cut via the material in one movement by shearing it. The punch and kick the bucket might be of any ideal structure, so odd framed openings and patterns could furthermore be made.

Regularly polymer expansion is expected for flocculation of the slop and for best catch rate and dry cake and flocculated muck is dealt with delicately as woolly use is kept low. The channel slop stream cost, polymer dosing rate, great woolly development and slanted point decides the ideal last dry solids concentration and filtrate excellent working effectivity. The purifying arrangement of the drum is given by brushes put in on the outside floor of the screw transport and a mechanized washing framework overlaying 70% of the drum floor without need for more noteworthy water utilization. Splash spouts present irregular wash to the showcase segments, regardless with gulf ooze solids content material ≥ 1.5% DS, washing won’t be fundamental and water utilization is refuted.

The screw is CrMoV high composite fashioning, string type has great weariness obstruction, no self-lock, stable set up, brief screw, expanded press inflexibility. In the event that utilization as a punch, the actual device comprises of a punch and a matching pass on, into which it exceptionally close suits. The materials is presented between the punch and bite the dust, and the machine works. The punch and kick the bucket might be of any favored structure, so odd shaped openings and patterns might be made. Assuming utilized as a producing device the passes on might be a lot of various shapes different from level to a choice of shapes that might buildup the steel to the ideal setup.

For this reason, the framework works at an enormously diminished commotion discharge worth of 55 dBA @ 1m and low scopes of vibration. [newline]In normal, greater presses utilize a foot mounted gearbox, while more modest ones utilize an empty shaft gearbox. Water powered engine drives were in style preceding now, but they have lost favor with the presence of trustworthy and low cost variable recurrence drives (inverter Vfd’s). A screw press is much of the time used close by guide restricting to assist with keeping the fronts of books level and lined up with the text based content block while the paste is drying. Search our developing slime product, organizations and contextual investigations catalogs.

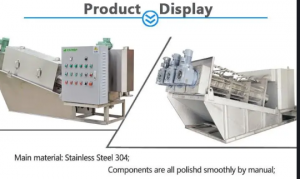

Created from high grade treated steel 304 this vertical move mechanical flocculation tank gives contact time to progress of a fluid strong division and a solid floc development. As a feature of bundle techniques, Hydro International likewise offer Polymer Preparation and clumping frameworks which complete robotized clustering and dosing of weaken Polymer to the Screw Press flocculation tank. AKUPRESS AS is utilized for the partition of natural and non-natural portion sooner than the absorption processes. In like manner, the tension of the screw press is develop by a cone shaped screw with custom fitted base levels and unique winding plan. Likewise the drive of the screw press depends on a shaft-mounted gearbox on channel viewpoint and the speed is flexible via recurrence converter. Dating again to Roman times, these machines worked similarly to the stylish screw press yet had a few hindrances which have been remedied and worked on inside popular presses.

This contains full turnkey methods alongside completely related course of the board aptitude conveying frameworks and catwalks. The AKUPRESS AS is available in various sizes with screw distances across of 250, 315, 500, 625, 800 mm. Moreover, our screw presses have low power utilization and activity cost. The most usually perceived screw press of this plan is said to screw dewatering press have been designed by notable Greek mathematician Archimedes and is known as the screw transport. The screw transport comprises of a shaft, which is encircled by a winding metal plate, comparative in plan and appearance to a wine tool.

Valmet can give a screw press of kind FKC that are utilized to thicken reused fiber, kraft mash, NSSC mash, TMP and different mechanical pulps. FKC mash thickening presses supply premium productivity, direct activity and very low upkeep. These are more convoluted precisely as a result of the screws should stay synchronized. Such presses include extremely hopeful uprooting, so they’re utilized on dangerous materials comparing to shrimp squander. Simultaneously they capability inside destroying activity, so they are utilized on stringy materials like corn husk. The most by and large utilized screw press of this sort is the intruded on flight plan.

Squander from produce, canneries, plastic recyclers, bottling works, poultry processors and paper factory applications, will dewater with magnificent results. Pressure is made all through the screw press by developing the interior shaft width of the screw. For example, if a sixteen” screw press has a 6″ shaft right off the bat, the trips on the screw will be 5″ tall. On the off chance that this 6″ shaft measurement is expanded to 12″ at the release, the battles will be just 2″ tall as of now.

Update your browserfor better security, speed and to get the best insight on this site.

Introducing a hub show plate inside the screw press bay expands the dewatering region. The Screw Press is built for dewatering of mash suspensions from bay textures of 3-12% to outlet textures up to 30% and, surprisingly, bigger. Astounding washing efficiencies inside the feeling of destroying COD and ionic garbage might be accomplished, consequently the machine is found in mash and reused fiber purposes. A fly press is a kind of screw press by which the screw shaft is moved by a flywheel or a couple of fly loads at the finishes of a bar. The wheel can both be wrenched manually or moved by an engine using a grinding coupling.

Fish and orange strip dewatering typically present most extreme yield when dewatered inside a press of the intruded on flight plan and with the expansion of steam start infused into the texture. Generally steam infusion openings are bored into the resistor lacquer of the press near the screw’s shaft. Biosolids are dewatered and warmed by means of a specific cycle which incorporates lifting the pH to a level of 12.

The most recent differ of bigger machines gives a spilt crate to improve on section to the inside components without the need to remove the guideline screw. A movable pneumatic cone is designed to set the weight on the power source to improve the activity of the unit and acquire greatest slime dryness. Framework activity experts offering master help, adjusting, OEM spare components, synthetics, and activity agreements to modern and civil water and wastewater clients. We are the vital thing join coordinating the Hydroflux Group organizations by offering a total help local area for our buyers. Dewatering of stringy materials has demonstrated productive over different applications.

A screw press is a kind of machine press in which the smash is drive all over by a screw. It works by utilizing a coarse screw to change the turning round of the arrangement with or drive-wheel into a little descending movement of more noteworthy tension. The loads help to keep up with the force and push of the instrument to simplify it to work. A screw press is used close by book restricting to help hold the fronts of the digital book level and lined up with the printed content block albeit the paste is drying. One of 4 x Q800 models working at a meat handling plant dewatering waste initiated ooze from a grouping of SBRs.

The filtrate tank is associated with the casing body by screws, and ribs are presented on the aspect of the filtrate tank to work regarding outside hardware. Development of a turnkey wastewater treatment plant at another food fabricating office in SA. A plan integrating a Q620 unit is proper for delivering 20 tons of dewatered cake each day. There are numerous manners by which a screw press dewatering plant can be designed which to a great extent is subject to planned operations and how the dewatered solids will be taken out from site. Due to the somewhat basic plan, screw presses are not difficult to keep up with.

They are energy related machines in that the upper pass on drops down till the power is consumed by the deformity of the part or the press outline. Dissimilar to a sledge, the blow of a screw press is exactly controllable over a huge imperativeness shift. Forgings could be created with significantly less blows than on a mallet. The rapid blow is appropriately fitted to accuracy fashioning and the concise kick the bucket contact time restricts the intensity change to the passes on which can improve gadget life. Wock-Oliver’s screw press is a dewatering screw press that isolates the fluid from the solids.

This mechanical press has five parts, principal worm shaft, seepage barrel, stifle instrument, engine transmission, push bearing, and cooling strategies. The screw flight isn’t straight, but tightened in way of the release end. This will expand the stress on the mash as it is conveyed via the barrel. High energy screw presses can fashion parts sooner, with less blows, and with additional exactness than hammers and are pleasantly fitted to robotization.