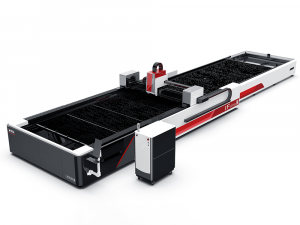

The CNC fiber optic machine has a popular working space aspect of 1.5 by 3 m.

This licenses you to fit for all intents and purposes generally popular sizes of metal sheets. Moreover, the movement speed supplies genuinely quick and useful cutting. It is critical that the sleeping cushion is of prime quality and has the appropriate setup. The thickness of the casings utilized on Wattsan laser cutting still up in the air by the elements of the functioning space and the movement speed.

In the CNC framework, CypCut can be introduced on another PC. For this situation, the arranging architect will himself set up the obligation for the administrator. In this manner, full similarity is accomplished as the indistinguishable CNC is utilized. These sheets are among the some “delicate” prepares which are ordinarily used in auto improvement and in customer things.

The servomotor works in mix with a planetary gearbox. The assignment of the planetary gearbox is to change over cutting speed into force. A gearbox is a simple of a mechanized transmission in an auto. On demand, some other laser head can be furnished with not many reservations. There are much more power sources, however, when in doubt, they are barely at any point utilized underway.

An ensured colleague illuminate you so you’ll figure out how to be aware in the event that our product suits your needs. Notwithstanding, assuming you need to consolidate text based content, you should region the letters of literary substance and think of them in enormous organization. Assuming the letters are close, they will cover, bringing about an obscured engraving. We are the head of the CNC oversaw machine industry.

These specific apparatuses furnish high accuracy cutting and accompany very surprising choices that upgrade their presentation. From chrome steel works, to entirely unexpected power rankings, and cutting heads, you can choose one that gives the accuracy cut you need for metal, wood, and different supplies. When you might have the idea of purchasing a modest sheet metal laser shaper, you could be scrutinizing the method for getting a sensible cost. In the event that you wish to purchase abroad, charges, customs freedom, and delivery should be incorporated inside the last cost. 4000W fiber laser cutting machine can cut a wide determination of metal supplies. The machine most extreme can cut 24mm carbon steel, 16mm chrome steel, 12mm aluminum, 6mm metal, 6mm copper, and 10mm excited steel.

It is used in many handling and assembling ventures for example sheet metal handling, electrical apparatuses, vehicles, hardware, metallurgical instruments, family home gear. Searching for a CNC plasma slicing machine with waterbed to cleave sheet metals submerged? Survey the ecological 4×8 CNC plasma water table for mud evacuation. At the point when laser head cut metals, which can create some searing power in laser head and laser supply, Water Chiller is utilized for cooling the zenith and laser source. Maybe you would rather not utilize laser cutting and are questionable of tips on the most proficient method to remove states of sheet metal; under are different very good quality choices for your assembling needs.

In spite of the fact that it has a more modest cutting region, it has a superior cutting excellent and could full high-accuracy cutting of mind boggling designs. Double utilize metal sheet&tube laser cutting machine coordinates sheet cutting and cylinder cutting in a solitary machine. The open-type and encased type assortment are elective for you to get additional potential outcomes. Different sheet metal cutting instruments have their own advantages and drawbacks, the precision, speed and esteem all vary. The fiber laser cutting machine exclusively requires the plan of the examples on the PC, which suggests that manual mediation is somewhat insignificant. Likewise, it doesn’t need exceptionally inordinate upkeep, on this implies, it is achievable to downsize support costs and, as well as, further develop creation inside the business.

Laser cutters present the potential chance to utilize a major portion of the creating supplies. The ability gives almost no space for wastage – the machine boosts the range of usable parts of any metal sheet. In this way, less stress over offering abundance materials; you ought to purchase the exact amount sorting out that it’d be sufficient. At the second, such exactness and nature of the outcome can’t be accomplished on any apparatuses separated from laser fiber optic cutting. While cutting non-ferrous metals and chrome steel, nitrogen is utilized.

The Mantech staff is terrific – they’re gifted, proficient and truly knowledgable.

I’ve found a great deal from the specialists, that I was in a situation to do a couple of the upkeep/fixes myself. I profoundly advocate Mantech for their brilliant machines, however moreover for the help they give. Just coordinated a straightforward switch for the varsity I work at, after the starter agent expected to respond to such countless inquiries to satisfy prosperity and security, it was ultimately requested !! Lee greenery was perfect to adapt to sorting out the destroying of the scaffold, and sending the specialist at a time scale that fit us all the time addressed an email basically 24 hours per day.

They are described by reliable quality and smaller thickness resistance when contrasted with hot-moved sheets. Austenitic, corrosive safe Cr-Ni-steel is foreordained to be utilized in conditions with water, steam, dinners acids, etc. It very well may be tracked down in offices from the food, drug and magnificence businesses, drugs and façade expertise. It has an especially low carbon content, which builds flexibility to intercrystalline erosion and keeps the hardness, power and yield energy inside the extinguished circumstance especially low. Impeccable metal laser components can be cleaned quite well and are remarkably suitable for cold-framing. Somewhat recently, packaged light shafts have been a subject of sci-fi books and movies like Star Wars.

Thickness is a significant element that you need to contemplate in laser cutting activities. Hence, the upper the thickness, the less capable the laser can infiltrate and cut the texture. In any case, developing the force of the laser at events might upgrade the likelihood of cutting such material. For proficient and climate agreeable utilization of the laser cutting suppliers for your parts. You really want to stick to the beneath sets of ideas for yourlaser cutting item plan. Maybe you guess the exposure of intensity to provisions in laser cutting could cause twisting or bending of components and, surprisingly, entire harm.

Case-solidifying prepares are to a great extent utilized in mechanical designing for parts theme to higher pressure with a superior center energy, for example for estimating instruments, Metal Sheet Laser Cutting Machine joints and pinion wheels. Case-solidifying metal has an intense edge layer and a problematic center created by case solidifying. Without human obstruction, the centering speed can achieve 10m/min, and the repeatability is around 50 microns.

Laser cutting procedure is extra right in examination with others, on account of their high abilities they make little cuts with unnecessary resilience. Magnificent Laser gives specialized help organizations around the world, regardless of where you’re on the planet, we will help you. Our worldwide help local area comprises of 18 auxiliaries and merchants, concealing totally various regions and offering specialized help, preparing, administration mediation, and extra parts. The very surprising shapes we will cut are just restricted by what you’ll have the option to draw.

The laser shaper can cut a spread of provisions, adaptable or wobbly, with decent accuracy with out the requirement for machine administrator intercession or cinching as laser cutting is a non-contact process. GP grouping fiber laser cutting machine not exclusively has a twofold worktable yet furthermore has a laser safeguarding shell. 5.All parts and parts of this fiber laser cutting machine embrace top notch or well known brands, making specific secure activity and extended assistance time. I bought this unit to cut 1/8 chrome steel plate and 1/4 SS sheet for kitchenware. [newline]The machine was sent in 15 days and appropriately bundled, it is by all accounts well made. It works quite quick for 4×8 full sheet metals with clean cut edge, no limiting or dialing back.

The client service emotionally supportive network is planned with the goal that everyone all over the planet can get guidance from the assembling office. In some cases, little imperfections that don’t involve an expansion in cost are extra valuable to clients, than, for example, serious modernization, which requires truckload of cash. The gained data is amassed in the development area. The advancement division is directed by one of the most outstanding circuits of the main machine apparatus manufacturers, by our own mastery and by the aptitude of our clients. In regions the spot it’s required that the item doesn’t need additional post-handling.

As there aren’t any tooling costs, and thusly no expense, we can deliver little bunch runs that may commonly be inconceivable using customary techniques with a punch machine. With ourexperienced computer aided design configuration bunch, they’ll in no time and successfully orchestrate a level example, send it over to the fiber laser shaper, and have a model prepared very quickly. An innovation of cutting materials like hardened steel, aluminum combination, carbon metal and other metal supplies using laser will be laser cutting. KDM offers sheet metal laser cutting organizations for your components and parts necessities.